In order to understand the results of this Condition Assessment one needs to familiarize with CETP; the concept of CETP is quite simple yet effective to treat the waste/effluent at a larger scale.

Common Effluent Treatment Plant (CETP) refers to the joint effort of treating the effluent generated at an industrial floc, the concept is more or less similar to Municipal Corporations of cities and towns treating the collective sewage of all individual houses. The size, location or nature of the industries may vary but the Guidelines of MOEFCC don’t and every industry is obliged to abide by them. For SME, MOEFCC issued guidelines in 1991.

Increasingly, New Industrial Development Corporations and Infrastructure Companies who are creating Mega Industrial hubs are promoting Industrial grade water & treatment of Effluent as an add on incentive to encourage investors.

CETP’s were initially introduced with the following objectives;

- Allowing SME to focus on the core business.

- Achieve ‘Economy of scale’ in waste treatment.

- Solve problem of space/land.

- Homogenization of wastewater for heterogeneous industrial cluster.

- Organizing proper centralized disposal of treated effluent & sludge.

The important environmental laws related to CETPs are:

- The Water (Prevention and Control of Pollution) Act, 1974

- The Air (Prevention and Control of Pollution) Act, 1981

- The Environment (Protection) Act, 1986 and The Environmental (Protection) Rules, 1986

- The Hazardous and Other Wastes (Management, Handling & Transboundary Movement) Rules, 2019

- The National Green Tribunal Act, 2010

- Public Liability Insurance Act, 1991

Role of CPCB & SPCB:

- Provide Guidelines and give consent to operate.

- Review & Monitor if performance is in-line with consent or not.

Role of National Green Tribunal (NGT):

- Public outcry of non-performance led to these cases being heard by National Green Tribunal, for simple understanding it’s a technical court.

- NGT now issues directives, and even has power to give closure notice. In some cases it has been closed also.

Aktion Consultancy had an opportunity to do the condition assessment of such existing CETP in Ahmedabad (Gujarat), this article will take you through the challenges providing the insights of the CETP summarizing its Condition Assessment results.

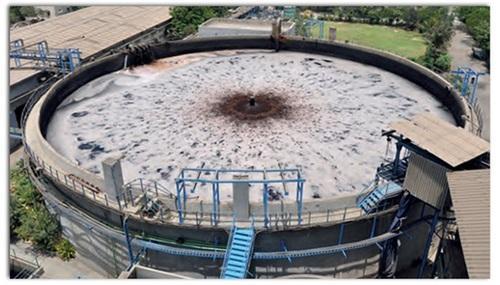

The CETP treated water from around 680 units in the industrial floc, it followed a treatment process sequence of chemical flocculation, equalization and aerobic biological oxidation. The CETP’s final treated effluent is discharged into a mega pipeline that leads to the local river body. At the time of study, some of the parameters in treated effluent did not meet the Inland Surface Water Discharge Standards.

Our findings suggested that there were several adequate and inadequate equipment in terms of capacity & efficiency. Overall the design of the plant was found to be excellent for such applications and overall operational observation summed up as satisfactory with proper operation logs, AM/PM schedule, data monitoring, data processing and review. The operating equipment were in continuous processing mode with sufficient automation so it was less dependent on operator’s alertness and skillset. The CETP works in compliance with SPCB norms and yields a good productivity without failures; also, it is remarkable to say that there were not any accidents or near miss reportings in last 3-4 years. Record keeping was performed with utmost care and some of the samples were also sent to the external laboratory for cross checking of results.

To sum up, there were challenges in design stage as couple of equipment found to be not designed well, such challenges cannot be mitigated by only operational support; the challenges in the operational area were however corrected meanwhile the challenges in performance were related to design and operation. Some new technology & equipment needed to be incorporated for the desired success of CETP.